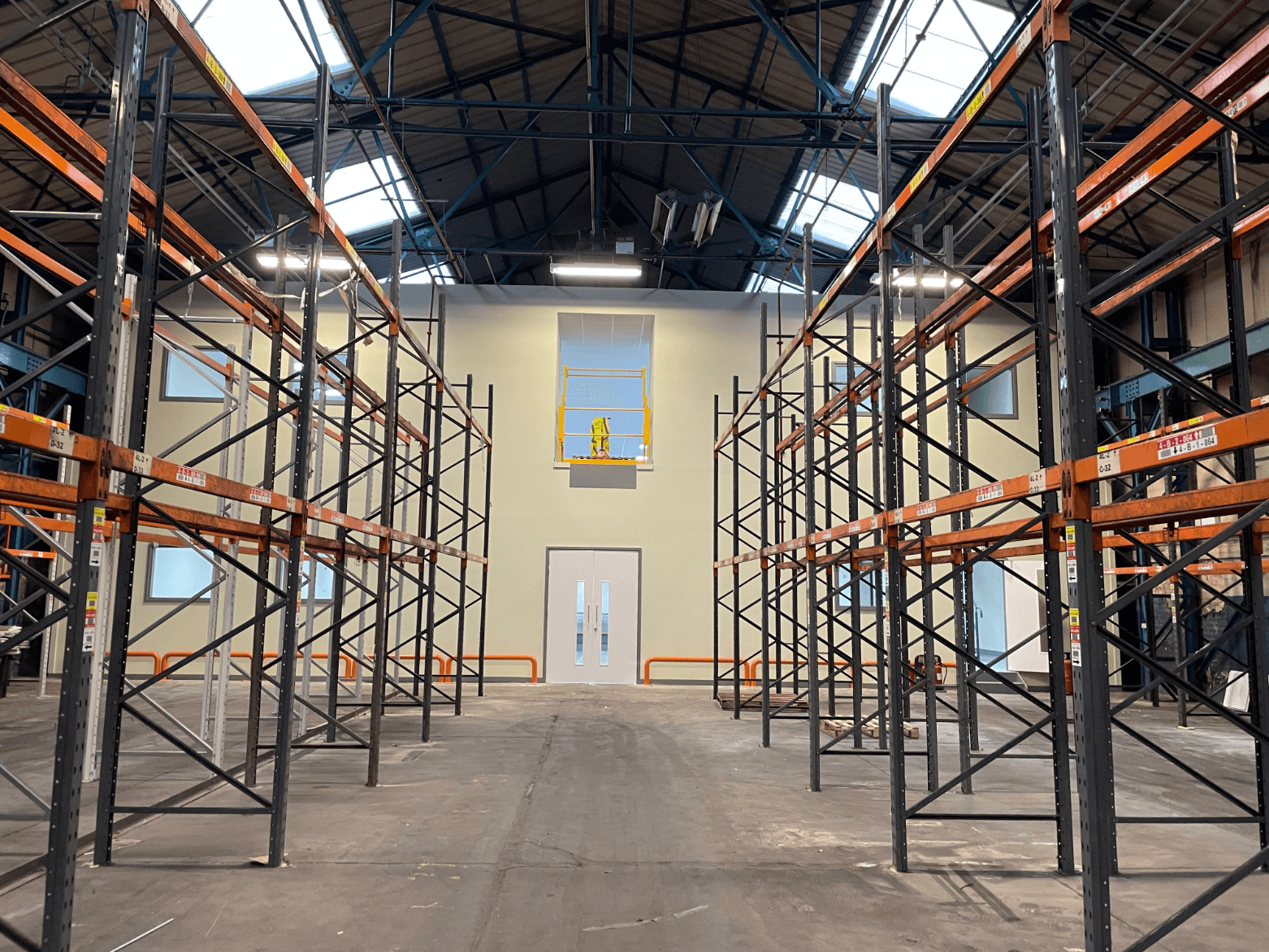

Wide Aisle Racking Systems

Wide aisle pallet racking is an extremely popular addition to any warehouse due to the unrestricted access to all pallets without the use of specialist equipment.

Contact Us

-

Design

-

Deliver

-

Install

-

Inspect

-

Repair

Wide Aisle Racking

Wide aisle racking units are versatile, flexible, and suited to all types of pallets, meaning they are ideal for use in every industry. The racking itself is sturdy, durable, and manufactured using reinforced steel in order to provide our customers with leading storage solutions for many years to come. Contact us for wide aisle pallet racking today.

Advantages of Wide Aisle Racking

Wide aisle racking presents a myriad of advantages crucial for efficient warehouse management. Offering heightened accessibility and manoeuvrability, this system facilitates seamless navigation for inventory retrieval without specialised equipment. Its adaptable nature accommodates diverse pallet types, fostering versatility across industries. Moreover, the system’s inherent flexibility streamlines stock management, enhancing operational efficiency. Cost efficiency becomes a potential hallmark, as optimised accessibility reduces time spent on retrieval, augmenting overall warehouse productivity. In essence, wide aisle racking signifies a pivotal asset, increasing warehouse storage efficacy and operational fluidity.

Structural Features and Design

Crafted from reinforced steel, wide aisle racking embodies structural robustness and resilience. This design choice ensures optimal load-bearing capacity, ensuring stored inventory safety. Customisable configurations cater to specific warehouse layouts, offering adaptability and maximising storage potential. The system’s design also encompasses a comprehensive approach to safety measures, integrating features that comply with industry standards. The structural versatility and safety-conscious design make wide aisle racking an ideal choice, assuring durability and functionality while prioritising safety within warehouse environments.

West Pennine Storage Equipment Limited have been working with us for a number of years, supplying and installing high bay pallet racking. All jobs were carried out to our complete satisfaction and I wouldn’t hesitate to recommend them.

David Slater, Operations Director, Meyer Group Ltd

UK Market Leading Solutions

West Pennine Storage Equipment is proud to be a Tier One design and installation partner for Link 51 and Apex Linvar. Our relationship with Link 51 and Apex allows us to design, deliver and install the highest quality, UK-manufactured racking at competitive prices. As we are a highly recognised distributor of all storage facilities, we are also able to supply all other major brands of Pallet Racking, Industrial Shelving and other Storage Systems.

Installation Process

Installing wide aisle racking involves a structured process designed for minimal disruption. Typically, the timeframe for installation depends on warehouse size and specific requirements. Before installation, preparation involves assessing space, ensuring adequate clearance, and verifying foundation integrity. Our professional installation services provide precision and adherence to safety standards, minimising potential disruptions to ongoing warehouse activities. While installation may briefly impact operations, the long-term benefits in storage efficiency outweigh the temporary adjustments required during setup.

Maintenance and Durability

Maintenance plays a pivotal role in sustaining the durability of wide aisle racking. Adhering to recommended maintenance practices ensures prolonged longevity. Regular inspections help identify potential wear and tear issues early on, allowing for timely repairs or replacements. This proactive approach safeguards against operational disruptions and extends the system’s lifespan. The durability of the racking system, coupled with conscientious maintenance, translates to sustained warehouse efficiency and optimised storage capabilities over the long term.

Safety Measures and Compliance

Wide aisle racking prioritises safety through stringent compliance measures and integrated features. The system aligns with industry standards, incorporating safety mechanisms that mitigate potential risks. Employees undergo comprehensive training to ensure adept usage, minimising accidents and damage. Safety features within the design, such as secure locking mechanisms and load distribution considerations, further enhance warehouse safety.