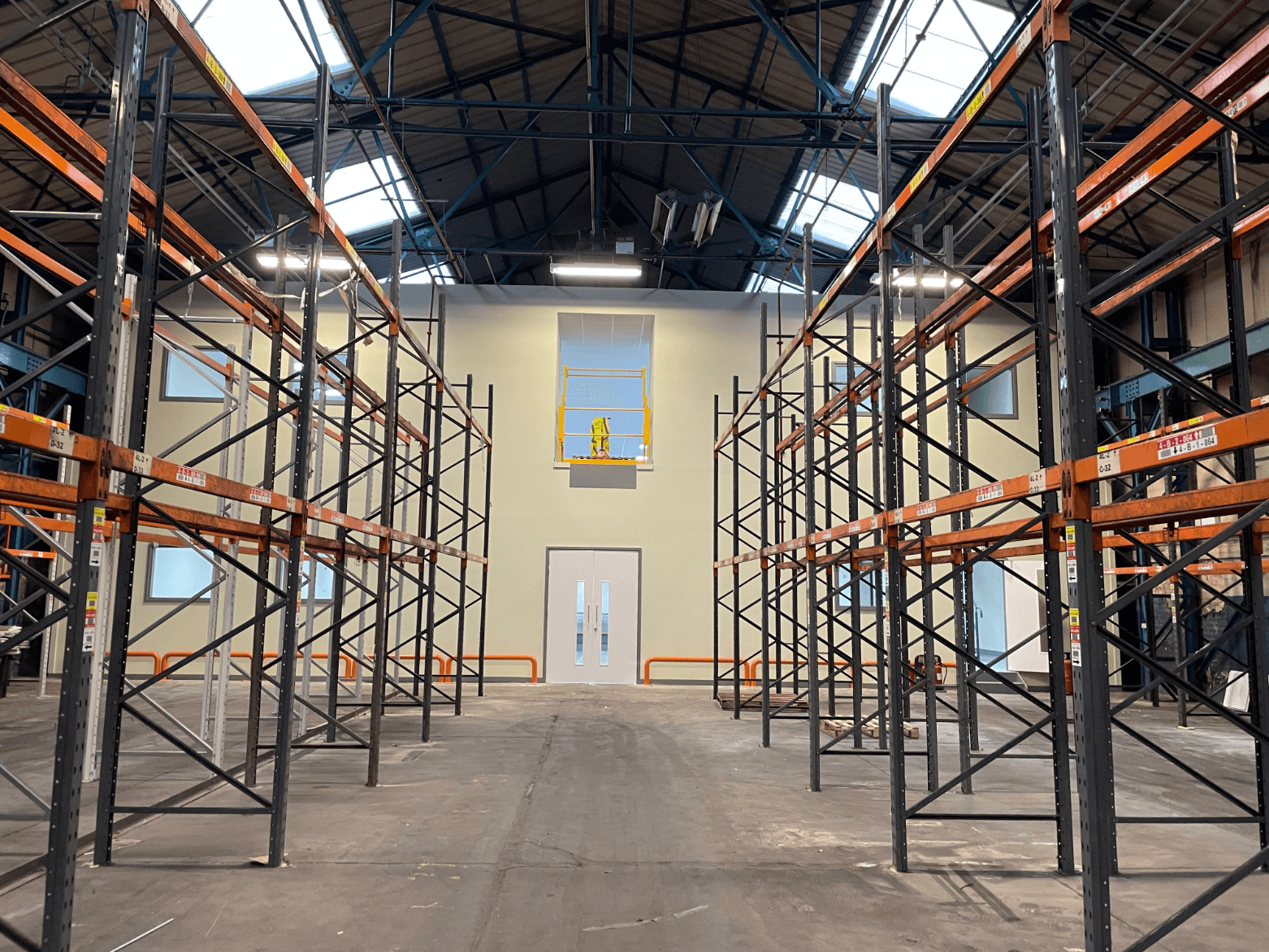

Pallet Racking Systems

As leading UK suppliers of pallet racking, West Pennine Storage Equipment will design, deliver and install a complete pallet racking management solution for your warehouse.

Contact Us

-

Design

-

Deliver

-

Install

-

Inspect

-

Repair

Pallet Racking

Our pallet racking systems are designed to suit any industrial environment, making it easier for you to maximise the efficiency of any warehouse facility.

At West Pennine Storage Equipment, we supply warehouse pallet racking for all sizes of warehouse and for the heaviest loading requirements of a pallet storage operation. our design service will maximise space utilisation even for complex layouts. In addition to this, our heavy-duty pallet racking is designed to store heavy pallets at height safely reducing the risk of injury.

-

Drive in racking

Start Your Project Today -

Narrow isle racking

Start Your Project Today -

Widespan racking

Start Your Project Today -

Push back racking

Start Your Project Today -

Double deep racking

Start Your Project Today -

Wide isle racking

Start Your Project Today -

Galvanised racking

Start Your Project Today -

Get in touch

Start Your Project Today